| Wood

cheeks for your MiniBrute |

| DISCLAIMER : Any modification to any MiniBrute will immediately void its warranty. Arturia or any of its affiliates will not accept responsibility for any damages, personal loss or injury that may result from any modification to the device. Should you apply any of the hacks and modifications described on this site, your own responsability alone is engaged. |

| Unmounting the

plastic cheeks |

|

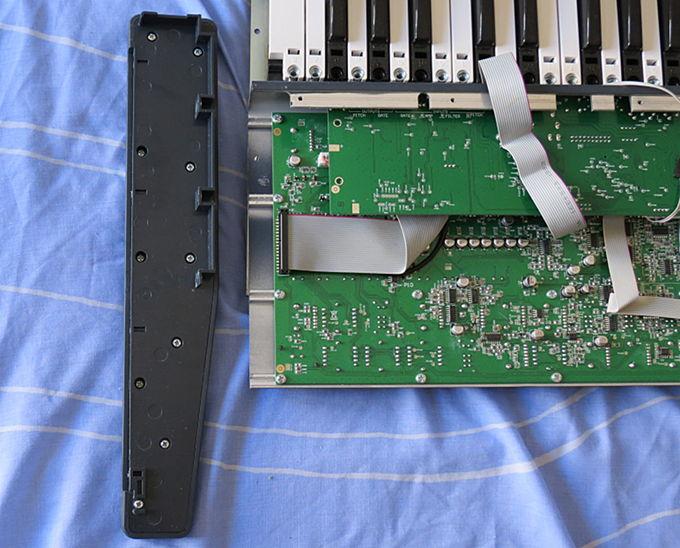

Put your MiniBrute upside-down on a

soft surface in order to avoid strain on the

potentiometers and keys.

Find, unscrew and put in a spare box : the twelve screws shown by the red arrows in the photo below. It is not necessary to unscrew the four screws on the front.  |

Gently remove the plate et tilt

backward the plate with the keybed. Make sure that you

don't stress the connection ribbons. Slide the font

plate underneath the potentiometers such that the back

of the keys of the keybed come in contact with the rear

plate of the MiniBrute as shown in the photo below.

|

Locate the four screws that secure

the plastic cheek to the chassis (red arrows in the

photo below).

Remove and spare them, then release the plastic cheek from the chassis. Do the same for the other plastic cheek.  |

Once freed it can be seen that the plastic flank is made of two components: the exernal cheek itself and a fixation plate. These are maintained together by ten screws.  |

The plastic cheeks must disasembled

to be used as a template for the cutting of the wood

pieces. Therefore remove the ten screws and spare them

in a box, then separate the cheek from the plate.

|

| Cutting out

the wood cheeks |

I chose to use birchwood for the

cheeks firstly because I like the grain or texture of

birchwood, and on second hand it can be crafted quite

easily with simple usual tools such as a handsaw to

cut-out the pieces, and a wood rasp to shape the pieces

and make chamfers.

I used a 20mm (0.787 inch) thick birch board originally

sold to be used as shelf board. |

Below the result of the cut wood piece obtained with the handsaw. The result is quite good indeed.  |

After shaping the round corners, chamfers and then polishing, the two birchwood cheeks are nearly ready. |

|

Now comes the tricky part, a long rebate (275mmx9mmx3mm) must be etched on the inner edge of the basis of the cheeks. If you have a router or a shaping machine. Otherwise it can be etched with a chisel but it is quite time consuming (that's what I did by the way ;-) ).  |

One of cheek with the rebate, and the second waiting to be etched...  |

| Mounting the wood cheeks |

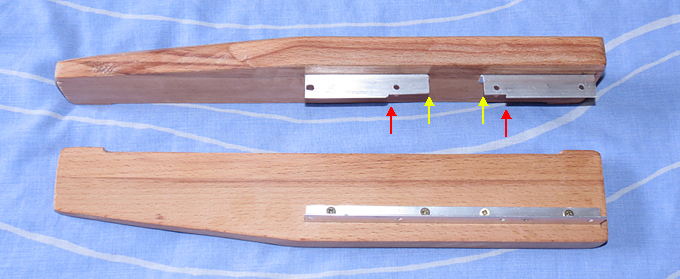

In order to secure the wood cheeks I used two L-shape aluminium (15mmx10mmx1.5mm) sold by the meter. I cut two pieces of 17.4 m.  |

After drilling the holes for the

fixation to the chassis (long side of the L) and those

for the fixation to the cheek (short side of the L). The

piece that is to be fixed in the left cheek must be cut

into two shorter pieces in order to leave space (yellow

arrows) for the potentiometer of the Pitch Bend wheel.

Further more a 2mm band (red arrows) must be filed away

to make room for the fixation plate of the wheels.

|

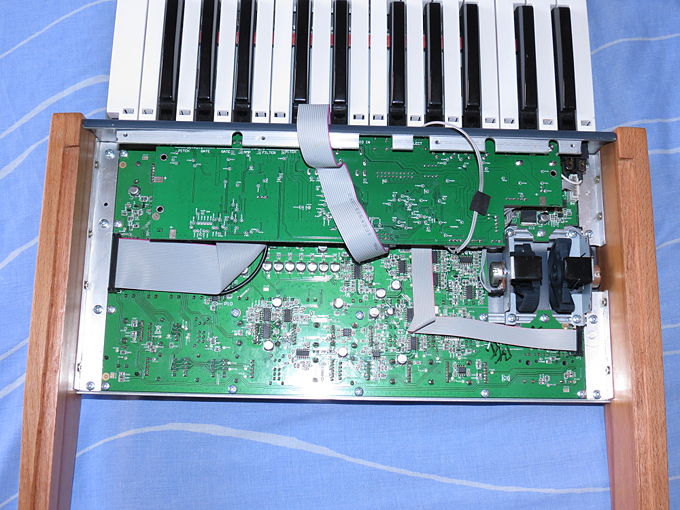

Now a quick assembly of all the parts to check that all is ok and fits.   Well ut seems I did a good work and

no adjustment is required. It is time give a nice

finish to the wood parts...

|

| Oiling and

waxing and assembling the wood cheeks |

To finish the cheeks I used liquid wax with a medium oak tint. After spreading a first layer, letting dry, polishing with a soft cloth, then adding a second layer, drying and polishing the woodcheeks we may proceed to the re-assembly. The photo below shows the two waxed wood cheeks. The small piece of raw birchwood on top of this photo makes it possible to see the effect of the waxing.  |

Now we can mount the cheeck to the chassis using the l brackets and the 8 fixation screws.  |

This view shows the details of

mounting of the left cheek et illustrates how the two

pices of L bracket come on the sides of the

potentiometer of the Pitch Bend wheel.

|

Now it is time to install the keybed and the bottom plate and secure it with its 12 screws.  |

There we are !  |

Two views of the MiniBrute back in the studio...   |